“The global AEC market size was valued at $7.1 billion in 2020, and is forecast to reach $1.5 billion in 2028, indicating a CAGR of 10.7% in 8 years.”

~ Global Opportunity Analysis and Global Forecast, 2021-2028 Report by Allied Market Research.

This stat shows that the architecture, engineering, and construction (AEC) industry is booming and will continue to thrive in the coming years.

However, it is important to note that the construction industry is experiencing a massive shift accelerated by the global pandemic.

It is evident from a fresh wave of changes this industry is witnessing in terms of working methodologies, technologies, safety practices, etc.

So, it is imperative for AEC firms to stay abreast of these transformations. This blog highlights the most remarkable trends every construction firm must adopt to maintain a competitive edge. But before that, let’s first get a brief idea of what the AEC industry would look like in the pre-pandemic times.

Business landscape of the AEC industry before the 2020s

Not long ago, or even until the 2020s, the AEC industry was one of the least digitized industries, and the degree of manual intervention was relatively higher. Even though large AEC firms leveraged advanced technologies, robots, drones, etc., to a certain extent, weren’t widely used in the industry as a whole.

It was mainly due to budget constraints and the subsequent inability to invest in advanced technology to replace manual jobs. Further, the high competition for tech-savvy professionals who could operate these smart machines made it challenging to hire and retain them.

Apart from this, earlier, AEC projects could not be easily outsourced to another location, i.e., all the workers, engineers, or architects involved would collaborate for work on the site. Geographically dispersed teams collaborating on projects through workflow management or video conferencing did not apply here. It is because there was little inclination to shift to virtual/remote collaboration or experiment with remote work prevalent across AEC firms before the pandemic times.

Moreover, even though environment-friendly construction has been around for some time, it was not a well-established norm. Green construction was relatively expensive. It required specific materials, technologies, etc., and most firms could not afford it. However, various international treaties and agreements raised awareness for sustainable building and boosted its demand.

Now that it is clear what the AEC industry was like before the 2020s, let’s understand the popular trends reshaping it.

Read More: A Detailed Guide to Construction Management Plans

Emerging trends of the AEC industry in 2022 and beyond

Due to a number of trends, the AEC industry landscape has transformed hugely to attain its current form and is set to evolve further.

Here are a few significant trends that construction firms must keep an eye on.

Emergence of hybrid construction project management

Unlike fully onsite construction projects until a few years ago, AEC firms today rely on onsite/offshore (or hybrid) models. In this model, various structures are built off-site and delivered to the construction site. The two most prominent onsite/offshore models are prefabricated structures and modular buildings.

A study reveals that the global modular construction market size is forecast to reach $108.8 billion by 2025.

Prefabricated structures include smaller parts like panels and sections pre-built in a factory under controlled environmental conditions, including temperature, humidity, etc. On the other hand, modular structures have comparatively larger components built with higher precision. They are delivered and assembled at the construction site to create a bigger structure. These models help reduce on-site wastage, ensure cost-effectiveness, deliver superior quality, and minimize turnaround times with lower labor costs.

Digital transformation for process automation

The use of digital technologies and solutions ranging from physical devices to on-field or in-office software has increased manifold. For instance, builders use self-driving vehicles to transport heavy materials across the site without any human intervention. Furthermore, AEC firms also leverage robotics and control systems to mix concrete, lay the cement, remove surface water, etc. It helps prepare precast and ready-mixed concrete products, install them faster, and minimize material consumption.

Digitalization also helps in the advanced rendering of the built environment using virtual reality/ augmented reality, BIM (Business Information Modeling), etc. For example, firms use reality capture that deploys laser scanning and unmanned aerial vehicle (UAV) photogrammetry to create the replica or “digital twin” of the project conditions. It allows remote inspection of existing conditions, reduces human errors, and helps identify and address challenges at an early stage.

Read More: 6 Effective Strategies to Create a Smarter Digital Workplace

Increased adoption of collaborative technology

While collaboration and communication would primarily be on-site and in-person earlier, the pandemic has led to a paradigm shift. Most AEC firms have realized the need for remote communication and coordination and are utilizing advanced collaborative solutions. This is the reason why several software solutions that provide a unified platform to connect AEC people are emerging.

Such software provides a centralized view into people and projects to allow real-time tracking of changes, facilitate efficient workflow management, and enable better schedule/budget estimates. They have also successfully replaced tedious and error-prone manual data entries, Excel spreadsheets, or CSVs, enhancing efficiency. Moreover, video conferencing and file-sharing apps enable real-time collaboration of AEC resources, expedite decision-making, and facilitate rapid problem-solving.

Ongoing shortage of skilled labor

Research reveals that the construction Industry is currently facing a shortage of 650,000 workers in 2022.

This shortage of labor can be attributed to multiple factors. First, the older generation workforce, especially baby boomers, are retiring, resulting in a large number of vacancies. Second, fewer millennials & Gen Z are interested in pursuing a career in the AEC industry. Therefore, firms are finding it challenging to refill roles such as on-site architect, engineers, or hourly craft positions.

Third,

AEC firms are struggling to attract employees after numerous resources were laid off due to a global recession triggered by the pandemic.

Fourth, frequent digital disruption makes it unfeasible for small-sized firms to implement suitable training programs to upskill the workforce on advanced skills like SketchUp, Revit Architecture, etc. Resultantly, skill obsolescence is rendering the existing workforce incompetent and insufficient to cater to evolving demands.

Read More: How Can Retraining/Upskilling Future-Proof Your Workforce?

Escalated equipment and material costs

The AEC industry is continuously facing supply chain disruptions due to global regulatory constraints after the pandemic. Moreover, the rise in international shipping costs and a backlog of domestic freight operations make the situation even worse. In addition, rising construction demand, decreased manufacturing productivity due to health protocols, and ongoing global economic crises have led to soaring costs of imported equipment and materials.

CBRE report reveals that the prices of almost all goods have gone up 41% in March 2022 from March 2020. Another major effect is that the lead time for the supply of several materials has gone up by several times. For instance, the lead time for roofing materials has increased by up to 40 weeks, and window doors and frames by 18 weeks. It, in turn, can cause a delay in the project closure stage.

Rise in the significance of labor safety

Multiple technological advancements have also facilitated efficient supervision of workers’ conditions. UAVs and drones have increased in popularity since they can replace the time-consuming on-foot inspection of the construction site. They can also pinpoint potential hazards like a heavy object’s exact location, unstable floors, etc., and help avert injuries and fatalities.

In addition, safety technology like Cat® Detect provides proximity-sensing systems that restrict machine movement in tight spaces. In addition, the cameras and other embedded sensors help operators to be aware of equipment and workers near machines. Besides that, the global pandemic has increased the need for a healthy and sanitized working environment to ensure employee welllness. Thus, they implement social distancing guidelines, distributing personal protective equipment (PPE) kits to workers, etc.

Read More: 8 ways to Support Employee Wellness in the Post-Pandemic Workplace

Growing emphasis on sustainable construction

The acknowledgment of the severe consequences of drastic climate change has propelled the demand for sustainability. Hence, AEC firms today are shifting to eco-friendly building measures on a large scale. One of the most noticeable trends in this direction is the increased use of solar energy. It enables them to supplement traditional power, save energy consumption costs, and preserve natural energy reserves.

In addition,

Biodegradable materials like grasscrete (green concrete), bamboo, bioplastics, etc., are fast-replacing traditional building materials used in foundations, walls, etc., to mitigate toxic waste and chemicals.

Further, green design technology is used to reflect sunlight and maintain an optimum temperature by lowering heat absorption. Thus, it effectively reduces the dependence on the air-conditioning system and decreases greenhouse emissions. Water-efficiency technologies, including dual plumbing, rainwater harvesting, etc., that help manage water and use it for myriad secondary purposes are also trending.

Now that we know about the latest trends in the AEC industry, let’s understand how resource management software can help firms adopt these trends.

How can resource management software help AEC firms adopt these trends?

A robust resource management solution can help an AEC firm adopt these trends and transform its business.

First, a resource management solution provides enterprise-wide visibility into human or non-human resources and their attributes. It also provides advanced filters like location and cost rate that help identify and deploy cost-effective global resources. This way, these filters contribute to protecting profit margins while keeping the end quality intact in hybrid projects based on mostly prefab or modular construction.

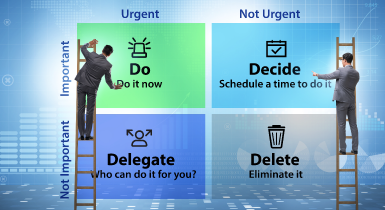

Second, this tool provides capacity-vs-demand and project vacancy reports that help identify the existing skill gaps and determine whether pipeline project demands are one-time or recurring. They also facilitate an in-depth analysis of requirements’ patterns across multiple pipeline projects to understand evolving skills that the workforce needs to be equipped with.

Accordingly, managers can hire and create a right blend of a permanent and contingent workforce and initiate upskilling/retraining programs to keep the workforce’s skill matrix updated and competitive. It is more useful for AEC firms that still rely heavily on human resources and need to build a tech-savvy workforce to digitize operations for sustenance.

Third, this tool provides forecast-vs-actual financial reports that help track the difference between the predefined and actual budget. If the actual budget spent on the work is more than the forecasted at any stage, the firm can investigate the reason and implement appropriate measures to minimize this negative variance and retain profitability. Also, the people-on-the-bench report helps view the resources to be released from various projects and deploy them proactively on the right jobs to minimize bench size.

All these functionalities together can help an AEC firm adapt to evolving industry trends effectively and efficiently.

Conclusion

“We shape our buildings; thereafter, they shape us” ~ Winston Churchill.

The architecture, engineering, and construction industry has undeniably been pivotal to civilizations for ages and play a crucial role in defining and transforming them.

However, it is imperative for AEC firms today to stay on top of path-breaking innovations and advancements that have the potential to redefine the entire industry. By adopting the above-discussed trends and implementing a robust resource management solution, an AEC firm can thrive and stay ahead of the competition.

So, which trends are you ready to welcome in your AEC firm?

The SAVIOM Solution

SAVIOM is the market leader in helping multinational clients manage their resources efficiently and effectively. With over 20 years of experience, this Australian-based MNC has a global presence across 50 countries and has helped 100+ clients with their Workforce Planning Software. Saviom also provides tools for Enterprise Project Resource Management, Project Portfolio Management, and Professional Service Automation.