Imagine a scenario where an electronics manufacturer is struggling to meet the fluctuating seasonal demands of room heaters. As a result, the manufacturer loses lucrative market opportunities, resulting in poor sales. In the following quarter, warehouses are overflowing with surplus unsold electric room heaters, leading to higher storage costs and tied-up capital. These inefficiencies disrupt supply chains, increase operational costs, and reduce revenue.

To overcome such challenges, businesses must implement a robust demand management framework. These strategies enable organizations to anticipate demand fluctuations, optimize supply chains, and enhance operational efficiency. Moreover, by striking the right balance between supply and demand, firms can maintain optimal inventory levels, improve product/service delivery, and boost competitive edge.

In this blog, we will explore the nitty-gritty of demand management, including its definition, benefits, challenges, process, and best practices.

But first, let’s go over the basics.

What is Demand Management?

Demand management is the process of forecasting, planning, and controlling customer demand for products or services to ensure a balance between supply and demand. It involves analyzing historical data, market trends, and customer behavior to make informed decisions about inventory and production.

Businesses use demand management to optimize stock levels, prevent shortages or overstocking, and improve overall supply chain efficiency. Therefore, it helps avoid financial losses from excess inventory while ensuring that products are available when customers need them.

Now, let us explore the differences between a few key concepts: demand management, demand planning, and capacity management.

Demand Management vs. Demand Planning

While demand management and demand planning are related concepts in business operations, they differ in their purposes.

Demand management is a broader process that involves forecasting, planning, and managing upcoming requirements to align with the business goals. It also ensures that the organizational capacity can meet fluctuating demand with ease. This helps optimize resource allocation, reduces operational costs, and enhances business profitability.

On the contrary, demand planning is a subset of demand management. It mainly focuses on predicting future demands by analyzing past data, market trends, and other external factors. This enables businesses to anticipate demand fluctuations and adjust supply chain operations accordingly. Consequently, it helps maintain an optimal inventory, streamline operations, and ensure financial viability.

Demand Management vs. Capacity Management

Demand management and capacity management are two distinct yet interrelated processes that help firms align supply & demand for operational continuity.

Demand management involves predicting, planning, and fulfilling customer needs to align with organizational goals. It involves multiple strategies, like pricing adjustments, campaigns, promotions, etc., influencing customer needs and allowing firms to balance supply with demand. This helps streamline processes, optimize inventory levels, and enhance overall profitability.

On the other hand, capacity management ensures that an organization’s production capabilities, workforce, and infrastructure can handle upcoming demand. It involves strategies such as equipment upgrades, process improvements, etc., to ensure production capacity aligns with demand requirements effectively and efficiently. This helps eliminate last-minute bottlenecks and unnecessary resourcing costs.

Now, let’s compare the differences based on key traits.

| Traits | Demand Management | Demand Planning | Capacity Management |

|---|---|---|---|

| Definition | A strategic process to forecast, influence, and regulate customer demand to align with business objectives. | A forecasting process that predicts future demand using historical data, market trends, and other external factors. | A process focused on ensuring sufficient resources, workforce, and infrastructure to meet evolving demand efficiently. |

| Objective | Balancing supply and demand through forecasting, pricing, and demand-shaping techniques. | Predicting future demand to optimize production, inventory, and supply chain operations. | Optimizing resource capacity to ensure seamless operations and prevent bottlenecks. |

| Key Activities | Demand forecasting, demand shaping, demand sensing, etc. | Analyzes past data, market trend analysis, and foreseeing project pipeline needs to forecast demand accurately. | Capacity planning, monitoring resource availability and utilization levels, and implementing strategies to close the resource gaps. |

| Scope | Broad, yet short-term. | A subset of demand management with a long-term focus. | Closely linked to resource management. |

Given this difference, let’s explore the essential elements of demand management.

Core Elements of Demand Management

Effective demand management relies on key components that enable firms to predict, regulate, and align demand with operational capacity. Let’s explore them.

Market Trends Analysis

This involves assessing industry patterns, customer behavior, market trends, economic indicators, and other external factors affecting demand. This proactive approach helps organizations stay ahead of demand changes, minimize risks, and seize growth opportunities.

Demand Forecasting

This process involves utilizing statistical models and historical data to predict future customer demand for products or services. This enables businesses to plan production and optimize inventory levels to meet anticipated demand effectively, enhance responsiveness, and stay competitive.

Capacity Planning

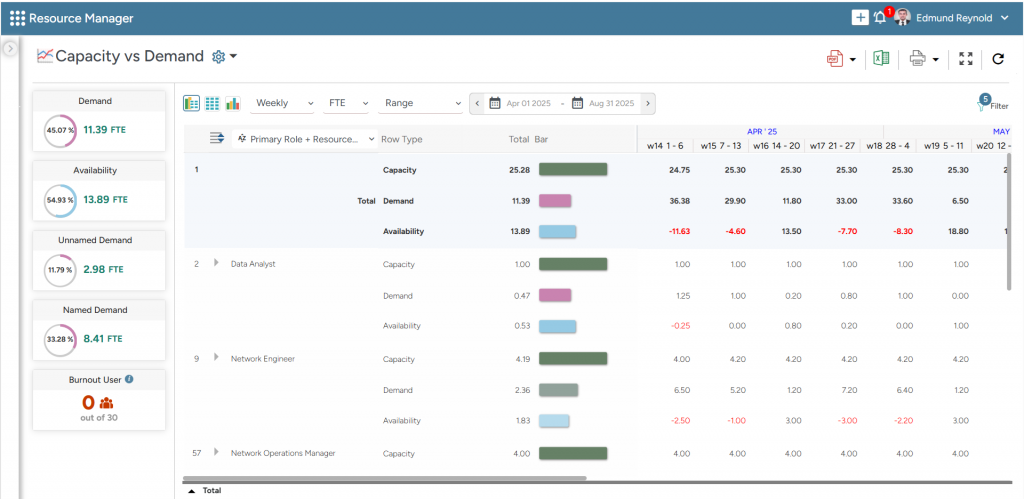

Businesses must perform capacity vs. demand gap analysis to evaluate an organization’s production capabilities, workforce, and infrastructure to meet future requirements. It ensures that resources are appropriately scaled to handle demand fluctuations without over-allocating or underutilizing assets.

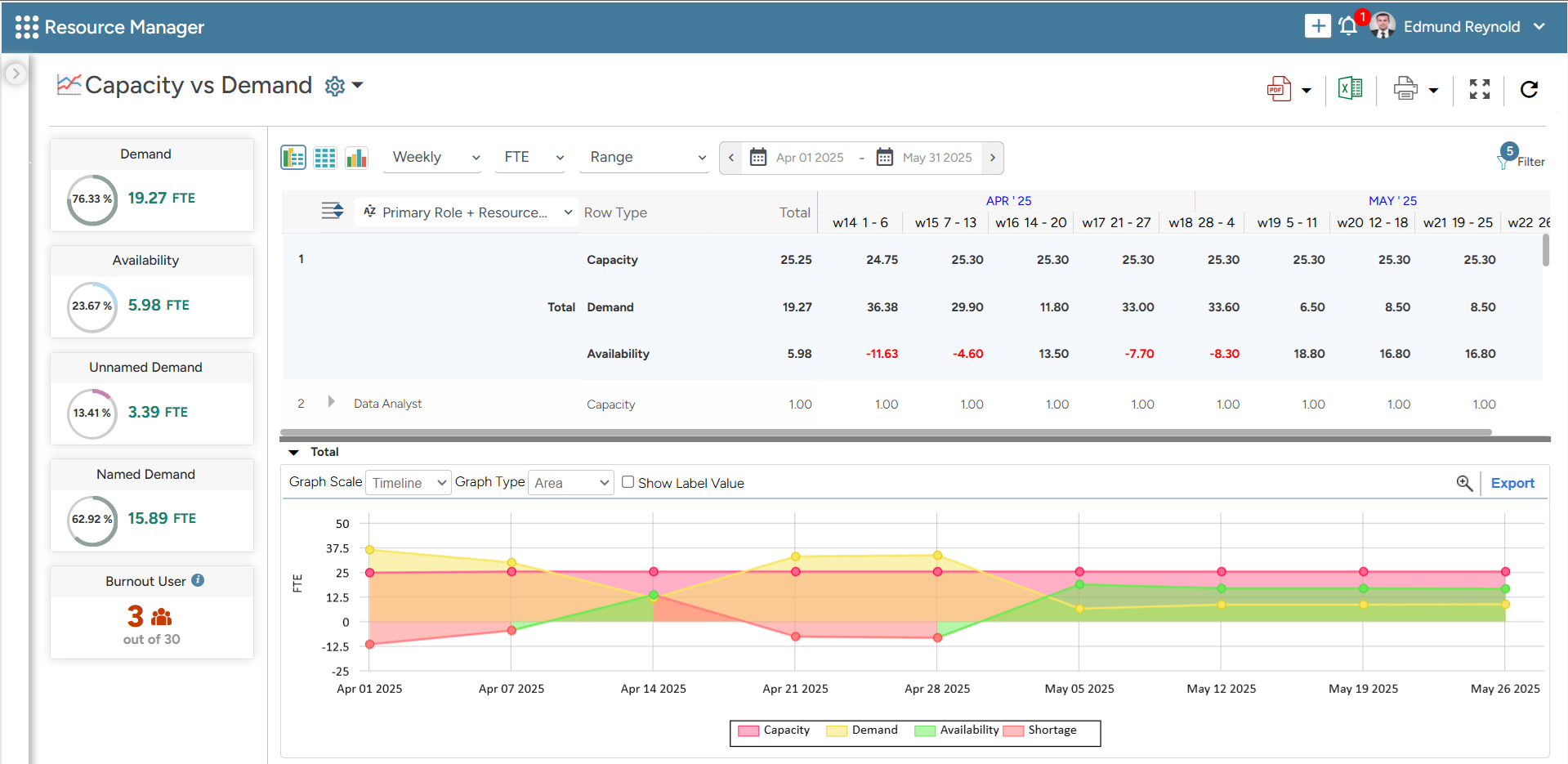

SAVIOM’s powerful resource Capacity vs. Demand chart allows managers to quickly evaluate employee shortage or excess and take necessary actions to bridge the gap.

Read More: What is Capacity Planning? An Ultimate Guide for Business Efficiency

Resource Allocation

It involves deploying available resources such as finances, personnel, and materials at the right time and cost to meet demand efficiently. Thus, proper resource allocation ensures that critical areas receive the necessary support to function efficiently, helping maintain productivity and control costs.

Process Optimization

This involves analyzing existing processes or workflows, identifying potential bottlenecks, and implementing best practices to eliminate redundancies. Further, by leveraging methods like automation or standardizations, firms can enhance their responsiveness to demand fluctuations and minimize operational costs.

Next, let’s explore demand management examples across different industries.

Demand Management Examples Across Industries

Given below are some examples –

IT industry

IT companies manage demand by forecasting server usage, software subscriptions, and cloud storage needs. They leverage data analytics and AI-driven models to anticipate traffic spikes, assess internal capacity, and allocate resources efficiently. This prevents system downtime, optimizes cloud costs & enhances user experience.

Read More: How Does the IT Industry Benefit from Efficient Workforce Planning?

Professional Services

Consulting, legal, and financial firms must balance fluctuating client demands with available expertise. Effective demand management involves understanding historical data & client projections to anticipate peak workloads and optimize service delivery accordingly. This improves process efficiency and enhances client satisfaction.

Manufacturing Industry

Manufacturers align production schedules, inventory levels, and supply chains with changing market demands. By using real-time data, historical trends, and market insights, they adjust production runs to prevent resource excess or shortages at the last minute. This helps maintain optimum inventory levels and minimize waste.

Construction Industry

Construction firms must consistently align labor, equipment, and materials with fluctuating project demands. This analysis enables firms to adjust procurement and staffing to ensure smooth operations, reduce cost overruns, enhance project delivery, and improve profitability.

Read More: Understanding Construction Resource Management: The Ultimate Guide

Now, let’s explore the benefits of demand management.

Benefits of Demand Management

Demand management enables businesses to proactively forecast service needs and identify potential challenges before they arise. Here’s a closer look at its key benefits:

Enhances Product or Service Delivery

Demand management helps forecast and determine customer needs, enabling businesses to align their inventory, workforce, and production accordingly. This minimizes the risk of stockouts or service disruptions, ensuring that products and services are delivered as expected, thereby enhancing the overall customer experience.

Minimizes Operational Costs

Effective demand management enables organizations to stay prepared and avoid last-minute scrambling for suitable resources. By efficiently aligning inventory, production, and labor needs, companies can significantly minimize operating expenses. It also enables firms to negotiate favorable supplier contracts and implement other cost-saving measures, leading to smarter spending and improved profitability.

Improves Inventory Management

Optimizing inventory levels is a key benefit of accurate demand management. By forecasting future needs with precision, businesses can maintain ideal stock quantities, reducing the risk of shortages or overstocking. This streamlines operations, cuts unnecessary expenses, and enhances overall supply chain efficiency, ultimately driving higher profitability.

Enhances Accuracy of Future Forecast

By leveraging historical data and market insights, companies can create more accurate forecasts. Demand management further refines this process by monitoring real-time market shifts and adjusting strategies accordingly. This continuous improvement allows organizations to reduce the risk of shortages or surpluses, ensure streamlined operations, and achieve long-term efficiency.

Read More: What is Resource Forecasting? A Guide for Project Managers

Boosts Client Satisfaction

When businesses accurately forecast demand and strategically align resources, projects or services are delivered on time and meet high-quality standards. This keeps expectations in check, minimizes last-minute firefighting, and streamlines execution. As a result, clients receive consistent, reliable service, which boosts client satisfaction and ensures long-term success.

Having explored the benefits of demand management, let’s now turn to the challenges businesses encounter during its implementation.

Demand Management Challenges

Managing demand fluctuations is complex, directly affecting supply chains, resource allocation, and customer expectations. Read on:

Inability to Predict Demand Fluctuations

Without accurate demand forecasting, businesses struggle to adapt to rapid market changes, leading to stock imbalances and supply chain delays. Moreover, external factors like technology trends, competition, and economic shifts can make traditional forecasting less reliable. Additionally, unexpected supply chain disruptions can further hinder planning, resulting in delays and revenue loss.

Read More: How Does Capacity Forecasting Help Build a Future-Ready Workforce?

Disparate or Limited Data Due to Information Silos

When data is scattered across departments, businesses lack a unified view of demand patterns. This fragmentation leads to inconsistencies in forecasting, inefficient decision-making, and misaligned inventory levels. Without seamless data integration, companies risk overproduction, stock shortages, and reduced supply chain agility.

Difficulty in Aligning Demand with Capacity

Balancing demand with available resources is complex, especially when production capabilities, workforce availability, and logistics constraints are not synchronized. Further, sudden demand spikes can strain operations, while excess capacity results in wasted resources. Ineffective alignment leads to inefficiencies, missed opportunities, and higher costs.

Read More: How to Measure Resource Capacity and Demand?

Reliance on Legacy Tools

Outdated systems and spreadsheets lack real-time analytics and predictive capabilities, making it harder to adapt to market changes. Moreover, manual processes further slow decision-making, hindering efficient demand management. Subsequently, it increases errors, reduces accuracy, and weakens supply chain resilience, making it challenging to respond swiftly to demand fluctuations.

Next, let’s take a closer look at the demand management process.

Demand Management Process

Demand management follows a structured approach to balance supply with demand. Here’s how it works:

Evaluate Past Data

Businesses analyze historical sales, market trends, and customer purchasing behavior to identify demand patterns and seasonal fluctuations. Leveraging reports and forecasting tools, they optimize inventory, minimize stock imbalances, and enhance operational stability.

For example, a footwear manufacturer reviews sales data from the past three years to identify peak seasons and slow periods. They notice increased demand for running shoes in the summer and formal footwear during the holiday season. This insight helps them prepare for upcoming demand spikes.

Assess Current Market

Next, firms must analyze recent sales patterns, competitor activities, and emerging industry trends. Further, they should monitor economic conditions and real-time demand signals. This enables them to make timely adjustments to inventory, staffing, and production, ensuring agility in operations.

Continuing the example, the footwear manufacturer notices a growing trend toward sustainable materials and rising demand for athleisure footwear. By analyzing competitor offerings and customer preferences, they adjust their production plan to introduce eco-friendly running shoes, aligning with market expectations.

Read More: Beat Market Volatility With Efficient Resource Capacity Planning

Forecast Future Demand

Using past data and current market insights, businesses predict future demand patterns. Advanced forecasting methods, including statistical models and AI-driven analytics, help ensure supply chain planning remains proactive rather than reactive. This enables timely allocation, reduces costs, and improves delivery efficiency.

For instance, based on their analysis, the firm anticipates a continued rise in demand for eco-friendly shoes. They use predictive analytics to adjust raw material procurement, streamline production workflows, and optimize distribution channels, reducing lead times and waste.

Formulate Demand Strategies

With a clear forecast, businesses must develop strategies to align supply with demand efficiently. It includes adjusting pricing, launching targeted marketing campaigns, optimizing distribution channels, and securing supplier agreements. This helps firms prevent last-minute bottlenecks and ensures business agility.

Building on this example, the footwear company leverages its forecast to introduce limited-time discounts on sustainable shoes before peak seasons. They collaborate with eco-conscious influencers to boost visibility and fine-tune production schedules to meet anticipated demand without overstocking or shortages.

Read More: What is Demand Planning & Why is it Important for Businesses?

Align Sales and Delivery Team

Next, firms must ensure seamless coordination between sales and delivery teams. Clear communication, synchronized workflows, and real-time data sharing help bridge gaps between order intake and fulfillment. This alignment improves market responsiveness, minimizes delays, and enhances customer satisfaction.

Further expanding this example, the manufacturer coordinates with sales and distribution teams to ensure seamless order fulfillment. By aligning production schedules with sales projections, they prevent stock imbalances and optimize delivery routes, ensuring customers receive their orders on time.

Review and Optimize the Process

Lastly, organizations must continuously assess performance and refine their approach. It involves analyzing sales data, customer feedback, and supply chain efficiency to identify gaps and areas for improvement. These regular reviews help firms enhance forecasting accuracy and streamline operations over time.

To conclude, the firm reviews sales reports post-peak season to evaluate the success of its sustainable shoe campaign. They identify production bottlenecks, renegotiate supplier contracts, and implement automation in production to enhance future demand management cycles.

Read More: What are Resource Constraints, and How Does It Affect Project Success?

In the next section, we’ll explore some best practices for effective demand management.

Demand Management Best Practices

The following demand management best practices help businesses optimize forecasting and align organizational capacity for a more efficient supply chain. Here’s how:

Gather and Centralize Demand Data

Establish a single source of truth by consolidating demand data from sales records, market trends, and customer insights. This facilitates agile decision-making, helps eliminate data silos, improves forecasting accuracy, and enables proactive adjustments to inventory and production.

Prioritize Demand Based on Business Objectives

Align demand priorities with strategic goals by evaluating financial impact, urgency, and feasibility. Use structured frameworks like MoSCoW or the Eisenhower Matrix to rank competing demands effectively. This ensures resources are allocated to high-value initiatives, maximizing business impact.

Read More: 25 Business Objectives That Every Firm Must Measure for Success

Foster Cross-Functional Team Collaboration

Facilitate cross-departmental collaboration between sales, operations, and finance teams to improve demand responsiveness. Conduct regular cross-functional meetings and use centralized communication tools for real-time data sharing. This improves transparency, ensures swift decision-making, and minimizes bottlenecks.

Develop Appropriate Contingency Plans

Identify potential disruptions such as supplier failures, logistics delays, or raw material shortages. Accordingly, firms can develop contingency plans such as securing backup suppliers, maintaining buffer stock, and adopting flexible workforce strategies. This mitigates disruptions and ensures operational continuity.

Read More: Risk Matrix in Project Management: An Ultimate Guide

Diversify Vendor Portfolio

Reduce dependency on a single supplier by building a diverse vendor network. Source materials from multiple suppliers across different regions to mitigate risks like delays, shortages, or price fluctuations. This ensures supply chain resilience and maintains operational stability during disruptions.

Leverage the Right Tools and Techniques

Integrate advanced technologies like data-driven analytics and demand forecasting tools to anticipate fluctuations with precision. Implement techniques like capacity modeling, scenario planning, etc., to enhance decision-making. This enables firms to respond swiftly to demand shifts, optimize costs, and ensure seamless operations.

SAVIOM’S Capacity vs. Demand graph and graph view display total demand and resource availability, helping managers make informed decisions.

Read More: Capacity Model: Definition, Types, and 6 Best Practices to Build a Robust One

Finally, let us explore how implementing powerful demand management software can benefit businesses.

How Does Modern Demand Management Software Help Businesses?

A robust demand management software helps firms provide real-time insights into various aspects of resources, thereby enabling timely product/service delivery. Here’s how –

- The all-in-one resource planner offers enterprise-wide visibility and helps supervisors establish a single source of truth. It also provides a consolidated view of every resource across different teams, departments, projects, and locations.

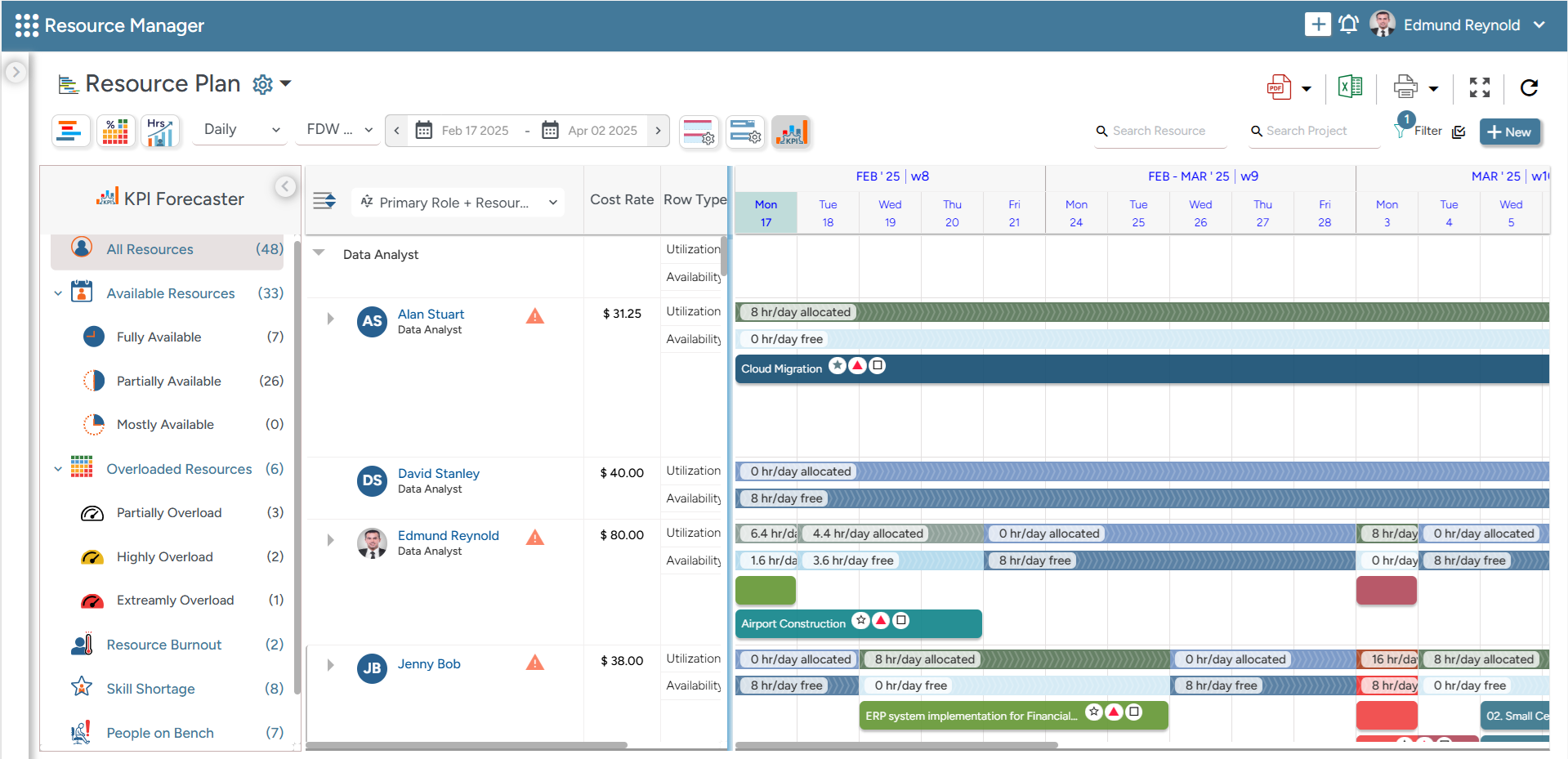

SAVIOM’s KPI Forecaster provides detailed insights into critical resource metrics like capacity, availability, utilization, etc., enabling proactive data-driven decision-making.

- The tool’s forecasting and capacity planning features help supervisors foresee pipeline project demand and understand potential resource shortage/excess. This facilitates timely actions like training, upskilling, or hiring to mitigate this gap effectively.

- Its intelligent KPI Forecaster provides early warnings on critical resource metrics, including underutilization, overutilization, people on the bench, skill shortages, and more, enabling proactive decision-making.

- The multi-dimensional scheduler allows firms to allocate the best-fit talent to tasks with an easy drag-and-drop function. It also enables them to make bulk bookings and edits to meet dynamically changing project demands.

- The embedded competency skill matrix allows managers to track and record every available skill, competencies, certifications, etc., within the firm. This enables them to identify and address skill gaps proactively.

- The real-time BI analytics, reports, and dashboards offer managers a detailed insight into demand fluctuations and other potential challenges like over/underutilization, enabling them to make quick, informed, and strategic decisions.

- Finally, the what-if analysis feature allows managers to simulate demand scenarios, assess potential resource constraints, and choose the most cost-effective plan.

Read More: How Can You Make Data-Driven Decisions with Resource Management Software?

Conclusion

“In the midst of chaos, there is also opportunity.” ~ Sun Tzu

This quote captures the essence of effective demand management. By anticipating fluctuations, prioritizing needs, and optimizing resource allocation, firms can turn uncertainty into a strategic advantage. Moreover, by implementing a demand management process coupled with a robust resource management tool, firms can enhance operational efficiency, improve agility, and stay competitive.

The Glossary

Read More: Glossary of Resource Workforce Planning, Scheduling and Management