Imagine a popular clothing brand running out of winter coats just as temperatures drop. Customers leave disappointed, and sales decline. The reason? Poor demand planning. Without accurate demand forecasts, the retailer failed to stock up on seasonal bestsellers, resulting in revenue loss.

Demand planning can help businesses avoid this scenario by ensuring they have the right inventory levels at any given time. It is a data-driven approach that integrates historical data analysis with market insights to forecast future customer demand. With a solid demand planning strategy, organizations can streamline operations, reduce business costs, and meet customer expectations.

In this blog, we will delve into the nitty-gritty of demand planning and the key steps for creating an effective plan.

What is Demand Planning?

Demand planning is the process of forecasting future requirements for a product or service. It involves analyzing past data, market trends, seasonality, and other relevant factors to understand pipeline demands.

Based on this analysis, organizations can determine the quantity and quality of goods or services required to meet these upcoming needs. Accordingly, they can take necessary measures to optimize inventory levels. This helps streamline operations, improve customer satisfaction, and drive financial performance.

Now that the definition is clear, let’s move towards the various elements of demand planning.

Elements of Demand Planning

Demand planning comprises the below-mentioned key elements:

Trade Promotion Management

Trade promotions are marketing strategies typically used in retail companies that focus on generating in-store demand through special discounts, giveaways, promotional offers, and other similar methods. It is designed to help companies stand out from their competition through well-coordinated promotional activities so that they can deliver all expected benefits. Additionally, this method helps build strong relationships with customers.

Product Portfolio Management

It is the process of managing every phase of the product lifecycle, from its initiation to end-of-life planning. The goal is to maintain a high-level view of the entire portfolio and understand where product lines are interconnected and interdependent. Moreover, it includes fitting new products into the existing portfolio while assessing their impact on other offerings to prevent cannibalization.

Read More: What is Project Portfolio Management and Why Is It Important?

Statistical Forecasting

Statistical forecasting analyzes historical data to generate supply chain forecasts using various advanced algorithms. In demand planning, it’s crucial to have data-backed forecasts to avoid overstocks or stockouts. This helps ensure optimal inventory levels, improve supply chain efficiency, meet future demand on time, and enhance overall business agility.

Data Sensing

Data sensing uses a combination of real-time data sources, such as economic indicators, government-backed reports, market conditions, and historical trends, to anticipate demand. It also leverages AI to detect patterns in consumer behavior. The goal is to create short-term demand plans and help companies adjust their supply chain and inventory management to meet upcoming requirements efficiently.

Now, let’s explore various demand planning methods.

Demand Planning Methods

Demand planners can apply various methods to accurately predict the upcoming requirements. Let’s take a look at them:

Moving Average Demand

This method utilizes historical data to predict demand for a product or service. It is primarily used for short-term planning and involves a statistical calculation that averages data points over a specific time period. Instead of considering each data point individually, the data is divided into subsets, and their averages are used to forecast demand while minimizing short-term fluctuations.

Linear Regression

This statistical technique forecasts future requirements using historical data while analyzing cause-and-effect relationships. Also known as the ‘line of best fit,’ it plots a curve based on past demand and extends it to predict future trends. Based on the least squares method, it helps identify correlations between demand and factors such as price, promotions, or seasonality, enabling businesses to make more data-driven decisions.

Seasonal Trends

This method allows demand planners to analyze historical sales data for a specific season, factoring in influences such as weather, festivals, and holidays to estimate future sales. It also considers seasonal patterns in consumer behavior toward a product or service. The primary goal is to better understand consumer behavior, ultimately enhancing customer satisfaction and service levels.

Sales Forecast

It is the process of estimating future demand for products or services by analyzing historical sales data, market trends, and business goals. It can be short-term, like predicting sales for the next month, or long-term, like forecasting annual growth. This forecast helps companies optimize their production schedules, staffing requirements, and inventory levels to meet pipeline needs effectively.

Time Series Analysis

It is a statistical technique that helps analyze and forecast data points collected or recorded at specific intervals. It involves examining patterns, trends, and seasonal fluctuations within historical data to predict future outcomes. For example, a company tracking five years of sales data can identify recurring periods when demand spikes, enabling more accurate forecasts and better planning.

To understand the demand planning process better, let’s look at an example.

Demand Planning Example

Consider an IT firm that provides cloud services to multiple clients. To effectively manage future demand, the company must have the proper infrastructure and workforce available at the right time and cost.

To begin with, the firm starts its demand planning by analyzing historical usage trends of its cloud services. Key actions include:

- Identifying peak periods and high-demand services from past data.

- Projecting future requirements based on client growth, seasonal spikes, and upcoming software releases.

Once demand projections are in place, the firm evaluates its infrastructure capacity and identifies gaps, if any. If additional resources are required, they take proactive measures, such as:

- Acquiring additional servers or expanding cloud storage.

- Hiring technical support staff to manage increased workloads.

- Collaborating with cloud service providers to enable quick scaling.

Next, with real-time monitoring, the firm continuously tracks usage patterns and adjusts resources as needed:

- Scaling up resources if demand exceeds expectations.

- Reallocating the workforce when demand drops, ensuring optimal operational efficiency.

This structured approach ensures seamless service delivery, prevents resource shortages, avoids unnecessary costs, and drives profitability.

Let’s look at the fundamental difference between demand planning and forecasting.

Demand Planning vs. Demand Forecasting: What’s the Difference?

While ‘demand planning’ and ‘demand forecasting’ are often used interchangeably, they refer to distinct concepts. Read on:

| Aspect | Demand Planning | Demand Forecasting |

|---|---|---|

| Definition | It is a process that helps align inventory, production, and resources with demand. | It involves predicting future demand for an organization’s products or services in a specified time period. |

| Core Difference | Using demand forecasts to prepare for and fulfill upcoming requirements efficiently. | Using demand forecasts to prepare for and fulfill upcoming requirements efficiently. |

| Focus | End-to-end supply chain readiness. | Estimating future sales or demand. |

| Scope | Broad – includes forecasting, inventory management, and supply planning. | Narrow – only focuses on predicting demand. |

| Timeframe | Focused on short- and long-term planning. | Primarily future-focused. |

| Data Used | Sales forecasts, inventory levels, and supply chain capacity. | Historical sales, market trends, seasonality. |

| Outcome | Ensures smooth operations and prevents stock issues. | Provides a demand estimate to guide planning. |

Read More: What is Resource Forecasting? A Guide for Project Managers

Now that the difference is clear, let’s learn about the various benefits of demand planning.

Benefits of Demand Planning

Effective demand planning helps businesses stay ahead of market changes, improve efficiency, and ensure customer satisfaction. Here’s how:

Helps Anticipate Future Market Trends

With effective demand planning, organizations can track patterns and predict shifts in customer preferences as well as industry trends. This allows them to adjust product offerings, pricing, and marketing strategies to stay ahead of the competitors. Moreover, this will enable them to increase their market share, differentiate their brand, and capitalize on emerging opportunities.

Ensures Resource Capacity Aligns with Demand

Accurate demand planning helps firms to align inventory, labor, and production capacity with forecasted needs. This enables businesses to prevent excess inventory or shortages, ensuring that the right resources are available at the right time and cost. This approach helps avoid last-minute procurement, streamlines production workflows and reduces inventory costs.

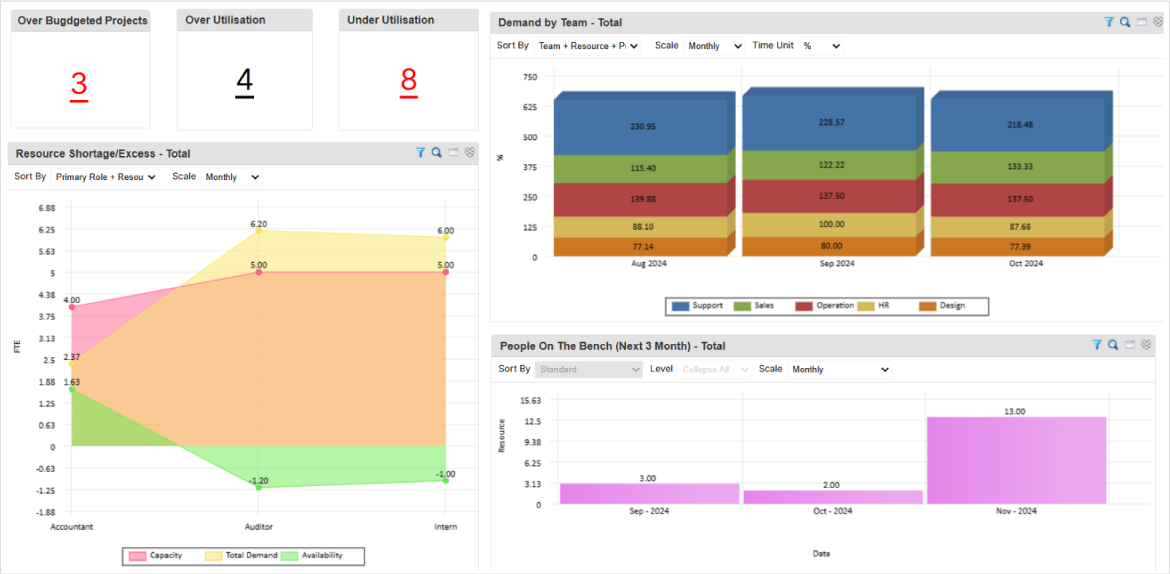

SAVIOM’s Capacity vs. Demand report helps managers assess and mitigate potential risks like workforce shortages/excess.

Minimizes Operational Costs

Proactive demand planning helps businesses match production capacity with future needs. This reduces last-minute procurement, ensures the right inventory levels, and supports smooth production flows while minimizing stockouts or overstocking. Consequently, it enhances supply chain efficiency, streamlines resource allocation, and reduces operational costs.

Read More: Reduce Resourcing Cost by 10-30% with Modern Resource Management Solution

Mitigates Resource-Centric Risks

With robust demand planning, companies can seamlessly identify potential risks, such as labor shortages or raw material scarcity. This early risk assessment enables firms to implement contingency strategies, such as supplier diversification, upskilling and cross-training programs, and more. These measures ensure the timely availability of the right resources, supporting seamless operational cycles.

Maximizes Business Profitability & ROI

With demand planning, businesses can anticipate future needs and streamline their supply chain operations. By efficiently allocating materials, labor, and equipment, firms can avoid delays, reduce inventory surplus or shortages, and optimize production processes. This boosts productivity, accelerates time-to-market, drives profitability, and enhances ROI.

After benefits, it’s time to learn some robust steps for effective demand planning.

7 Steps for Successful Demand Planning

The below-mentioned steps can help demand planners create a robust plan that aligns with business goals and objectives.

Create a Core Team

The first step is to create a team that includes members from sales, marketing, finance, supply chain, and operations. This ensures that all perspectives shaping the demand plan are considered, avoiding siloed decision-making. Additionally, assign clear roles so that every team member knows their responsibilities well.

For example, if marketing plans a major campaign, the supply chain team must adjust inventory to meet the surge in demand. Similarly, for a new product launch, operations should ensure sufficient production capacity. These regular check-ins across cross-functional units help ensure alignment and keep the demand plan relevant.

Collect & Organize Internal Data

Secondly, gather all relevant internal data, such as past sales data by channel and location, out-of-stock rates, inventory turnover, lead times, production times, obsolete inventory, and other key inventory metrics. Next, centralize this information in a single system to avoid inconsistencies or errors.

Additionally, consult sales and marketing teams to account for planned price changes, promotions, and campaigns that could influence demand. Similarly, coordinate with product teams to incorporate upcoming launches and competitive offerings, as these factors directly affect demand accuracy.

Make a Preliminary Forecast

Next, supervisors must leverage past sales data and current business trends to create an initial demand forecast. This will serve as a starting point for setting your future demand predictions. Additionally, don’t rely on any kind of assumptions and keep the estimates realistic.

For example, a business aiming to sell electronics can look at previous years’ sales patterns to estimate future demand. If growth has been steady, they can plan for a modest increase in production. Later, they can refine this estimate using external data such as industry reports and competitor activity.

Read More: How Does Capacity Forecasting Help Build a Future-Ready Workforce?

Assess & Integrate External Data

After making an initial forecast, incorporate additional insights such as economic conditions, competitor launches, and shifts in market demand. External factors like changes in raw material costs, new regulations, or supply chain disruptions can have a significant impact on demand.

For example, if raw material prices increase, the firms may adjust the forecast to account for potential price hikes. Similarly, if competitors launch similar products, shifts in demand could occur, prompting the supervisor to take necessary measures to avoid stockouts or losses.

Develop a Statistical Demand Forecast

In the next step, collaboratively decide on the type of forecasting model (or models) that aligns best with your business and then start building a forecast based on statistics and data. Moreover, consider leveraging robust demand planning software that can help create a realistic forecast and save time.

For example, in a business where the demand fluctuates seasonally, time series analysis can prove to be beneficial. If the sales remain steady, a moving average approach may work better. Leveraging the tool along with various forecasting methods can help identify the most effective strategy and boost overall business efficiency.

Read More: Capacity Model: Definition, Types, and 6 Best Practices to Build a Robust One

Compare Demand Against Capacity

Once the statistical forecast is ready, check if there are enough resources to support it or not. For this, compare the projected demand against production capacity, workforce availability, and inventory levels. In case of variances, implement necessary measures to bridge the gap ahead of time.

For example, if an IT firm expects a surge in demand, it can secure hardware components or software licenses in advance to avoid supply chain delays. In case they anticipate workforce shortages, they can hire contingent staff. By aligning capacity with demand, firms can minimize disruptions and ensure timely delivery of products.

SAVIOM’s resource capacity vs demand dashboard helps managers to match suitable talent with pipeline project requirements accurately.

Reassess & Refine the Plan as Necessary

Demand planning is a continuous process, not a one-time task. So, in the last step, track key performance indicators (KPIs) to measure the effectiveness of your demand planning and set targets for each. Additionally, track actual sales and compare them with your forecast and if you see any gaps, adjust your plan accordingly.

For example, if a product that usually sells well suddenly sees lower demand, identify the cause and tweak your inventory plan to avoid overproduction or financial loss. Staying flexible and making regular adjustments can help respond to market changes effectively.

Now that the steps are clear, let’s explore some best practices to strengthen the demand planning process.

Best Practices for Demand Planning

Effective demand planning requires a structured approach. The following best practices can help businesses enhance accuracy and efficiency.

Collect Comprehensive Data for Analysis

To ensure accurate demand planning, it is crucial to collect comprehensive data, including sales history, market trends, customer behavior insights, and relevant external factors such as economic conditions. A thorough data collection process enhances the precision of demand forecasts and enables more informed decision-making.

Enhance Cross-Departmental Communication

Demand planning impacts various teams, including sales, marketing, supply chain, and finance. Therefore, it is essential to establish clear and transparent communication protocols to ensure seamless collaboration, alignment on goals, and a swift response to changes.

Read More: 9 Effective Ways to Empower Cross-Functional Teams

Get Stakeholder Buy-in Regularly

Successful demand planning needs support from key decision-makers in finance, operations, and sales to make forecast assumptions and planning strategies. Regular check-ins help align expectations, address concerns, and adjust plans based on real-time business needs.

Choose the Right Tool for Forecasting

Businesses should choose a resource forecasting tool that meets their unique needs, offering key features like data integration, advanced analytics, scalability, real-time insights, and more. This will enable businesses to stay agile, keep pace with growth, and adapt to shifting market conditions effectively.

Further, let’s look at what the future holds for demand planning.

The Future of Demand Planning

The future of demand planning is closely tied to digital transformation. The Internet of Things (IoT) provides businesses with real-time data on inventory, raw materials, and demand trends. This immediate access to information helps improve forecast accuracy and optimize inventory management.

Cloud-based collaboration tools are enhancing the connectivity between teams, allowing for faster communication and quicker responses to demand changes. This enables businesses to remain agile and ensure that their supply chain operates efficiently.

With digital demand management, IoT and real-time analytics offer greater control over inventory. These technologies help businesses prevent stockouts and overstocking, leading to more effective supply chain management, improved operational efficiency, and increased profitability.

Finally, let’s see how a resource management tool can help in effective demand planning.

How Can a Modern Resource Management Tool Help?

Advanced resource management software empowers businesses to forecast, plan, and fulfill future demand, driving greater efficiency. Here’s how:

- The tool offers 360-degree visibility into key attributes such as capacity, demand, availability, cost, etc. This enables firms to identify suitable resources for future demand.

- The software’s advanced forecasting and capacity planning capabilities enable managers to assess and mitigate potential resource shortages/excesses beforehand.

- The real-time business intelligence reports and intuitive dashboard provide data-driven insights into key performance metrics, such as resource efficiency, inventory levels, etc., helping businesses make informed decisions.

- The modeling & simulation feature helps generate multiple scenarios and their outcomes by adjusting metrics such as capacity, demand, availability, cost rate, etc., to arrive at a well-suited resource plan.

Read More: How Can You Make Data-Driven Decisions with Resource Management Software?

Conclusion

Demand planning is not a one-time thing; it is a continuous process that helps optimize sales forecasting, inventory management, and supply chain operations. By following the above-mentioned steps and best practices, firms can create an accurate demand plan that anticipates and meets pipeline requirements, enhances operational efficiency, and fosters business growth.

So, are you ready to create a robust demand plan and boost your business’ productivity?

The Glossary

Read more: Glossary of Resource Workforce Planning, Scheduling and Management